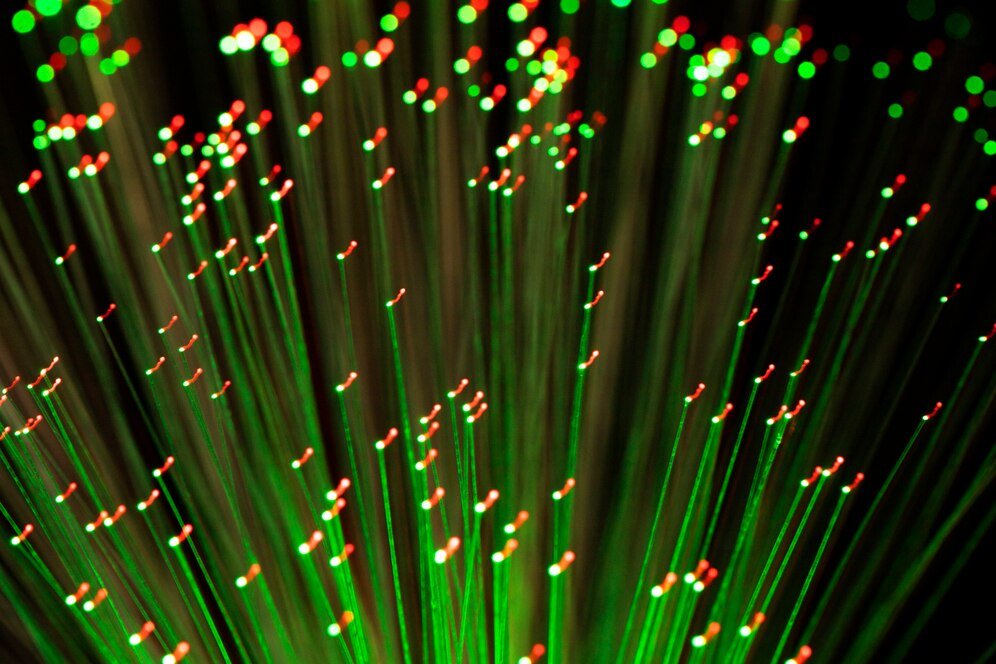

Accurate temperature measurement is now essential for optimum efficiency, safety, and performance in many processes in contemporary industries. Conventional temperature sensors, though pervasive, are susceptible to high temperatures, electromagnetic interference, and hostile operating conditions. Enter the fiber optic temperature sensors with their singular advantage. Optical fibers are employed by such sensors to generate precise, real-time temperature readings with no sensitivity to electrical noise or hostile operating conditions.

How Fiber Optic Temperature Sensors Function?

Fiber optic temperature sensors function on the basis of the transmission of light via optical fibers. The sensor system contains a light source, optical fiber, and detector. When the fiber is subjected to temperature variations, the light wavelength, intensity, or polarization changes. These are converted to calculate the precise temperature. Fiber optic sensors are distinct from conventional sensors in that they do not utilize electrical signals, rendering them highly resistant to interference and ensuring reliable performance in high-risk applications.

Key Advantages of Fiber Optic Temperature Sensors

Following are the main advantages of fiber optic temperature sensors:

High Sensitivity and Accuracy

Fiber optic temperature sensors provide accurate temperature readings with minimal deviation. Their high sensitivity to even minor temperature changes makes them ideally suited for applications where accuracy is paramount, such as semiconductor manufacturing and biomedical research.

Electromagnetic Interference (EMI) Immunity

Fiber optic temperature sensors are resistant to electromagnetic fields as opposed to traditional electrical sensors. Because of this, they are used in environments with high electrical noise, such as power plants, industrial furnaces, and MRI machines utilized in the medical field.

Large Temperature Range

These sensors are able to withstand extreme temperature ranges, thereby have applications in aerospace, metallurgy, and underwater exploration. This robust design will never allow their accuracy to deteriorate even under the highly unstable condition.

Chemical and Corrosion Resistance

Optical fibers being non-metallic in nature with materials like glass or quartz make them highly resistant to corroding chemicals and extreme industrial conditions. This feature makes them longer lasting and maintenance more cost-effective.

Real-Time Monitoring

Fiber optic temperature sensors are able to measure the temperature continuously and in real-time. This is extremely useful in oil and gas operations where small changes in temperature are vital signs of an imminent safety hazard or equipment failure.

Light and Compact Structure

Fiber optic temperature sensors are also lightweight, slim, and can be easily flexed into compact spaces. Installation in such tightly packed spaces is very convenient when there are very complex industrial installations where sensors become difficult to fit.

Uses of Fiber Optic Temperature Sensors

Power Generation and Energy

The thermal and nuclear power plants need precise temperature reading to ensure the efficiency of these plants and not overheat them. Fiber optic temperature sensors provide precise readings independent of electrical noise.

Oil and Gas Industry

Pipelines and refinery real-time temperature measurement in the oil and gas industry is a critical application to prevent leakage, safety, and optimal performance. Sensors are immune to hostile environments and operating temperatures.

Medical and Biomedical Applications

Fiber optic temperature sensors also enjoy widespread use in medical equipment such as MRI systems, heat sensing, and minimal invasive therapies. EMI immunity gives them unambiguous reading capacity without interfering with precise medical apparatus.

Aerospace and Defense

The aerospace sector requires high-precision measurement of temperature in defense technology, jet propulsion, and space exploration. Fiber optic sensors provide constant reading even at harsh conditions such as vacuum and high altitude.

Manufacturing and Industrial Operations

Fiber optic temperature sensors are required for use in chemical processing, semiconductor production, and steel production, where temperature monitoring at high temperatures is necessary for quality. Fiber optic temperature sensors provide continuous process parameters and prevent defects.

Automotive Technology

Luxury automobile technologies such as electric vehicles (EVs) and hybrid technology require precise thermal management. Fiber optic sensors enable battery temperature monitoring, engine heat, and exhaust systems for improved performance and safety.

Aspects to Keep in Mind When Choosing a Fiber Optic Temperature Sensor

Working Environment – The kind of fiber optic sensor to employ is a function of whether it will be utilized in high temperatures, corrosive environments, or areas with high electromagnetic interference.

Range of Measurement – Different applications require sensors with different temperature ranges. Utilizing a sensor that is suitable for the specific working environment ensures accurate measurements.

Sensitivity and Accuracy – Sensitive sensors are most suitable to be utilized in applications where accurate thermal monitoring is required, e.g., semiconductor manufacturing and biomedical research.

Cost and Life – While the cost of the fiber optic temperature sensors is quite high compared to the traditional sensors, their long life and minimal maintenance aspect guarantee them as an economical option in the long run.

Compatibility with Existing Systems – Compatibility of the existing monitoring systems should be considered to facilitate easy data collection and analysis.

Future of Fiber Optic Temperature Sensors

Demand for fiber optic temperature sensors will accelerate with rising industrial automation, IoT-based monitoring, and smart manufacturing. Adoption of AI and ML into monitoring systems will take predictive maintenance to the next level and enhance efficiency. In addition, development in fiber optic technology progresses towards miniaturization and lowering the cost of the sensors to encourage applications in other sectors.

Why Choose a Reliable Thermowell Supplier?

Fiber optic temperature sensors cannot be beaten in terms of accuracy, longevity, and resistance to harsh environments in high-accuracy temperature measurement applications across various industries. They are not affected by electromagnetic interference while providing real-time output, thus unavoidable in sensitive applications. Selecting a thermowell supplier means establishing parameters such as sensor quality, potential for customization, and integration potential to meet the distinctive needs of industries.

Tempsens Instruments (I) Pvt. Ltd. is a leading thermal and cable products firm and specialist in fiber optic temperature sensors for multi-purpose industrial applications. Its Indian, German, and Indonesian manufacturing plants guarantee high-quality temperature monitoring devices for accuracy, reliability, and durability. As thermal engineering experts, Tempsens is the ideal choice for those industries looking for advanced sensor solutions.

For more information on high-performance fiber optic temperature sensors, learn about Tempsens’ extensive line of thermal solutions today.