In the textile industry, ensuring the quality and durability of fabrics is paramount. A critical instrument in achieving this is the fabric tensile tester, which measures the tensile strength and elongation properties of textile materials. This essay explores the significance of fabric tensile testers in quality assurance and product development, highlighting their operational principles, applications, and impact on industry standards.

Understanding Fabric Tensile Testers

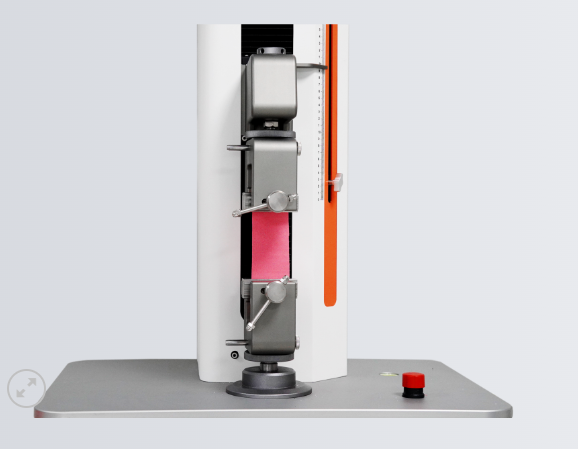

A fabric tensile tester is a specialized device designed to evaluate how textile materials respond to tensile (pulling) forces. By applying a controlled force until the fabric sample breaks, the tester provides valuable data on the material’s tensile strength and elongation. This information is crucial for manufacturers to ensure that their products meet specified performance criteria and can withstand the stresses encountered during use.

Operational Principles

The testing process involves several key steps:

- Sample Preparation: A fabric specimen is prepared according to standardized dimensions to ensure consistency in testing.

- Mounting: The specimen is securely clamped between two jaws of the tester; one remains stationary while the other moves to apply tension.

- Testing: The movable jaw pulls the fabric at a constant rate, recording the force applied and the corresponding elongation until the fabric ruptures.

- Data Analysis: The collected data is used to generate a stress-strain curve, from which key metrics such as tensile strength and elongation at break are derived.

Applications in Quality Assurance

In quality assurance, fabric tensile testers serve several vital functions:

- Compliance Verification: Ensuring that fabrics meet industry standards and regulations is essential for market acceptance. Tensile testing verifies compliance with standards such as ISO 13934 and ASTM D5034.

- Batch Consistency: Regular testing of production batches helps maintain uniformity in fabric quality, identifying any deviations that may occur during manufacturing.

- Performance Prediction: Understanding the tensile properties of fabrics allows manufacturers to predict how materials will behave under various conditions, aiding in the selection of appropriate textiles for specific applications.

Impact on Product Development

During product development, fabric tensile testers provide insights that influence material selection and design decisions:

- Material Innovation: Testing new or modified fibers and weaves helps in developing fabrics with desired strength and flexibility characteristics.

- Design Optimization: By understanding the limits of fabric performance, designers can create products that balance aesthetics with functionality and durability.

- Cost Efficiency: Identifying the optimal materials that meet performance requirements without unnecessary over-engineering can lead to cost savings in production.

Conclusion

Fabric tensile testers are indispensable tools in the textile industry, underpinning both quality assurance and product development processes. By providing precise measurements of tensile properties, these instruments help ensure that fabrics not only meet regulatory standards but also fulfill consumer expectations for durability and performance. As the industry continues to evolve, the role of fabric tensile testers will remain central to innovation and quality in textile manufacturing.

Essay 2: Advancements in Fabric Tensile Testing Technology

The textile industry has witnessed significant technological advancements, particularly in the realm of fabric tensile testing. Modern fabric tensile testers have evolved to offer enhanced accuracy, efficiency, and versatility. This essay examines the latest developments in fabric tensile testing technology and their implications for textile manufacturers and researchers.

Evolution of Fabric Tensile Testers

Traditional fabric tensile testers were primarily mechanical devices requiring manual operation and data recording. With the advent of digital technology, contemporary testers now incorporate computerized systems that automate the testing process and data analysis. Features such as touch screen controls, high-precision load cells, and sophisticated software have become standard, improving both user experience and data reliability.

Key Technological Advancements

- Digital Control Systems: Modern testers utilize digital interfaces for precise control over testing parameters, allowing for customizable test protocols and real-time monitoring.

- High-Precision Load Cells: The integration of advanced load cells enhances the accuracy of force measurements, enabling detection of subtle differences in fabric strength.

- Automated Data Analysis: Sophisticated software processes test data to generate comprehensive reports, including stress-strain curves and statistical analyses, facilitating informed decision-making.

- Versatile Clamping Mechanisms: Innovations in specimen grips, such as pneumatic clamps, accommodate a wide range of fabric types and thicknesses, ensuring consistent and reliable testing.

- Integration with Quality Management Systems: Connectivity features allow testers to interface with broader quality management and laboratory information systems, streamlining data management and compliance reporting.

Implications for the Textile Industry

The advancements in fabric tensile testing technology offer several benefits:

- Enhanced Accuracy: Improved measurement precision leads to more reliable data, supporting higher quality standards and reducing the risk of product failures.

- Increased Efficiency: Automation reduces the time required for testing and data analysis, accelerating the product development cycle and enabling faster response to market demands.

- Greater Flexibility: The ability to test a diverse range of materials and adapt to various testing standards allows manufacturers to explore new fabric innovations and applications.

- Improved Compliance: Seamless integration with quality management systems ensures adherence to industry regulations and facilitates audits and certifications.

Future Trends

Looking ahead, fabric tensile testing technology is poised to incorporate further innovations:

- Artificial Intelligence: AI algorithms could analyze test data to predict fabric performance trends and identify potential issues before they arise.

- Internet of Things (IoT): IoT-enabled testers could provide real-time data to centralized monitoring systems, allowing for proactive maintenance and calibration.

- Sustainability Metrics: Future testers may assess environmental impact factors, such as the energy required to produce a fabric of certain strength, aligning with the industry’s move towards

- In the textile industry, ensuring the quality and durability of fabrics is paramount. A critical instrument in achieving this is the fabric tensile tester, which measures a fabric’s tensile strength and elongation properties. By applying controlled tensile forces to fabric samples, these testers provide essential data that inform quality control processes.

The operation of a fabric tensile tester involves clamping a fabric specimen between two jaws—one fixed and one movable. The movable jaw exerts a pulling force at a constant rate until the fabric ruptures. Throughout this process, the machine records the force applied and the corresponding elongation, generating a stress-strain curve. This curve is instrumental in analyzing key metrics such as tensile strength, elongation at break, and fabric stiffness.

Implementing fabric tensile testing within quality assurance frameworks offers several

Universal Tensile Tester;Tensile Strength Tester

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com sales@tes.hk